Your How to cut square tubing angles images are available. How to cut square tubing angles are a topic that is being searched for and liked by netizens now. You can Get the How to cut square tubing angles files here. Get all royalty-free vectors.

If you’re searching for how to cut square tubing angles images information connected with to the how to cut square tubing angles interest, you have come to the ideal site. Our website always gives you suggestions for seeking the highest quality video and picture content, please kindly surf and locate more enlightening video content and graphics that fit your interests.

How To Cut Square Tubing Angles. Just keep it nice and firm and avoid cutting off your thumb. Making accurate cuts on aluminum rods tubes and angles is easy with a miter saw and a blade designed to cut nonferrous metal check the label. The classic is the Chop Saw but you can also put smaller discs on a circular saw or on a die-grinder. Just start cutting from one point and go through to make a square cut this requires pretty advanced skill to do properly You can mark a line and just trace it around the pipe freehand quick but not very reliable – this requires some skill but not anywhere near as much.

Add a sketch at the side of the tube with 15 degree angle you want make sure the sketch is closed then do an extrude cut through all. Spray a little lubricant a couple times while cutting and it will cut easy. Most cuts are at an angle not just straight so bundle cutting isnt usually an option. Just keep it nice and firm and avoid cutting off your thumb. Simply create a 45 angled sketch line on an appropriate origin workplane and then Split with Part option. Youll toast your blade after maybe 100-200 cuts but thats probably more than you need.

The circular saw method is how I built my first race car tube frame The Chop saw is a great way to cut steel with straight square cuts and most angles.

You are judged not by what you know but by what you. How to Hold the Aluminum Angle If youre doing straight cuts like with the angles all set to zero then you should be just fine holding the aluminum with your hand. Simply create a 45 angled sketch line on an appropriate origin workplane and then Split with Part option. You can cut aluminum with a plain old carbide tipped miter saw blade. The circular saw method is how I built my first race car tube frame The Chop saw is a great way to cut steel with straight square cuts and most angles. Cant explain how to find the dimensions between the cuts but Thomas can - buy the book.

Source: youtube.com

Source: youtube.com

Contiguous selectable area for the extrude. So for a 90 degree 4 piece turn would be 90 divided by 6 3 welds in a 4 piece turn 15 degrees. 01-19-2003 0820 AM. Actually you probably dont need to create a 45 workplane. Spray a little lubricant a couple times while cutting and it will cut easy.

Source: forum.onshape.com

Source: forum.onshape.com

I cut a lot of square and rectangular tubing. How to Cut Pipe Angles Accurately - Kevin Caron - YouTube. Wall thickness range from 16ga to 11ga. Youll toast your blade after maybe 100-200 cuts but thats probably more than you need. Several tips can help to ease bending square or rectangular material and reduce the amount of distortion in bent sections.

Yes youre probably right. Due to the nature of part too Ill need to hit a pretty tight tolerance and I think itll be easiest to get it exact by cutting all the way through then welding together. How to Cut Pipe Angles Accurately - Kevin Caron - YouTube. Simply create a 45 angled sketch line on an appropriate origin workplane and then Split with Part option. You are judged not by what you know but by what you.

Source: kartfab.com

Source: kartfab.com

I was always under the impression a cold saw was the tool for the job. Using a pattern to cut the end can lead to lots of grinding or filing to get a good fit on thick-walled tube. How to Cut Pipe Angles Accurately - Kevin Caron - YouTube. Angle of cut number of degrees in turn divided by number of welds x2. Put the tube where you want it butted up against the other tube and measure the gap you haveFor the other angle Mark the measurement of the gap on the side you butted.

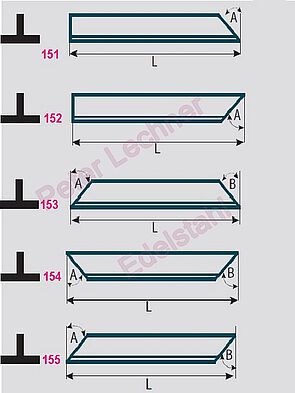

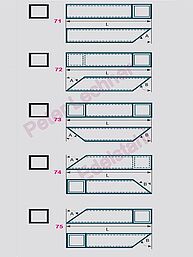

Source: edelstahl-lechner.de

Source: edelstahl-lechner.de

Simply create a 45 angled sketch line on an appropriate origin workplane and then Split with Part option. Then connect the cornersmr-t. Put the tube where you want it butted up against the other tube and measure the gap you haveFor the other angle Mark the measurement of the gap on the side you butted. 2 level 1 stpeteexpert 6y A hacksaw and a miter box should do the trick. Just keep it nice and firm and avoid cutting off your thumb.

Source: forums.sketchup.com

Source: forums.sketchup.com

The other methods are quicker and give better results. About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy Safety How YouTube works Test new features. Making accurate cuts on aluminum rods tubes and angles is easy with a miter saw and a blade designed to cut nonferrous metal check the label. Use the dremel to clean up the burs. Bending round square or rectangular material involves stretching the outside diameter OD of the bend and compressing its ID.

Source: youtube.com

Source: youtube.com

The notch and fold is more difficult to pull off with 12 square tube than saw a larger profile. Becomes a hassle at times to force everything to project and select to a. Anywhere from 12 to 4 square. An angle grinder with a welders razor blade will do it but not accurate or repeatable. Actually you probably dont need to create a 45 workplane.

Simply create a 45 angled sketch line on an appropriate origin workplane and then Split with Part option. Just keep it nice and firm and avoid cutting off your thumb. Theres a multitude of ways to cut steel tubing including an old-fashioned hacksaw. Autodesk Inventor 2019 Certified Professional. Yes youre probably right.

Source: youtube.com

Source: youtube.com

Quick Tip - Cutting Round Tubing - YouTube. Just start cutting from one point and go through to make a square cut this requires pretty advanced skill to do properly You can mark a line and just trace it around the pipe freehand quick but not very reliable – this requires some skill but not anywhere near as much. If you want to check them out this one is the 7-14 blade and this one is the 10 blade. You could also put the sketch on the centerline of the tube and do the extrude cut both ways from the center. Bending round square or rectangular material involves stretching the outside diameter OD of the bend and compressing its ID.

Source: youtube.com

Source: youtube.com

Typically If your using a 14 chop saw with 18 thick tube and thinner and the tube is say 2 x 3 you should be fine but thats about as big as I recommend. You could also put the sketch on the centerline of the tube and do the extrude cut both ways from the center. Spray a little lubricant a couple times while cutting and it will cut easy. That should slice off the end of your tube. How to Cut Pipe Angles Accurately - Kevin Caron - YouTube.

Source: kartfab.com

Source: kartfab.com

Put the tube where you want it butted up against the other tube and measure the gap you haveFor the other angle Mark the measurement of the gap on the side you butted. Fact is if youre fabricating something aside of butting together high pressure with code welds pipe most cases its actually easier to end up with squareprecise angles after welding if the cut is slightly off. Wall thickness range from 16ga to 11ga. That should slice off the end of your tube. Another method is to create a sketch on the end of the tube and revolve a.

Source: youtube.com

Source: youtube.com

Most people use something called a Joint Jigger to cut the pieces to fit. The circular saw is more maneuverable cheaper and smaller than a Chop saw. Just start cutting from one point and go through to make a square cut this requires pretty advanced skill to do properly You can mark a line and just trace it around the pipe freehand quick but not very reliable – this requires some skill but not anywhere near as much. I was always under the impression a cold saw was the tool for the job. If the motor housing on your saw is open and could collect metal chips tape a piece of cloth over the openings to protect the motor windings and bearings while you cut the aluminum.

Source: youtube.com

Source: youtube.com

Yes youre probably right. Autodesk Inventor 2019 Certified Professional. Becomes a hassle at times to force everything to project and select to a. If you want to check them out this one is the 7-14 blade and this one is the 10 blade. Youll toast your blade after maybe 100-200 cuts but thats probably more than you need.

Source: edelstahl-lechner.de

Source: edelstahl-lechner.de

02-26-2009 1259 PM. Cut Aluminum with Your Miter Saw. The other methods are quicker and give better results. Most cuts are at an angle not just straight so bundle cutting isnt usually an option. If you want to check them out this one is the 7-14 blade and this one is the 10 blade.

Source: youtube.com

Source: youtube.com

An abrasion chopsaw is fairly. I cut a lot of square and rectangular tubing. Quick Tip - Cutting Round Tubing - YouTube. So for a 90 degree 4 piece turn would be 90 divided by 6 3 welds in a 4 piece turn 15 degrees. Yes youre probably right.

This site is an open community for users to do submittion their favorite wallpapers on the internet, all images or pictures in this website are for personal wallpaper use only, it is stricly prohibited to use this wallpaper for commercial purposes, if you are the author and find this image is shared without your permission, please kindly raise a DMCA report to Us.

If you find this site convienient, please support us by sharing this posts to your preference social media accounts like Facebook, Instagram and so on or you can also save this blog page with the title how to cut square tubing angles by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.